How is the production method of white bitumen?

The method of producing complete white bitumen with the details ...

The highest quality natural bitumen in Iran

gilsonite (bitumen)

Exploration and extraction of bitumen mines

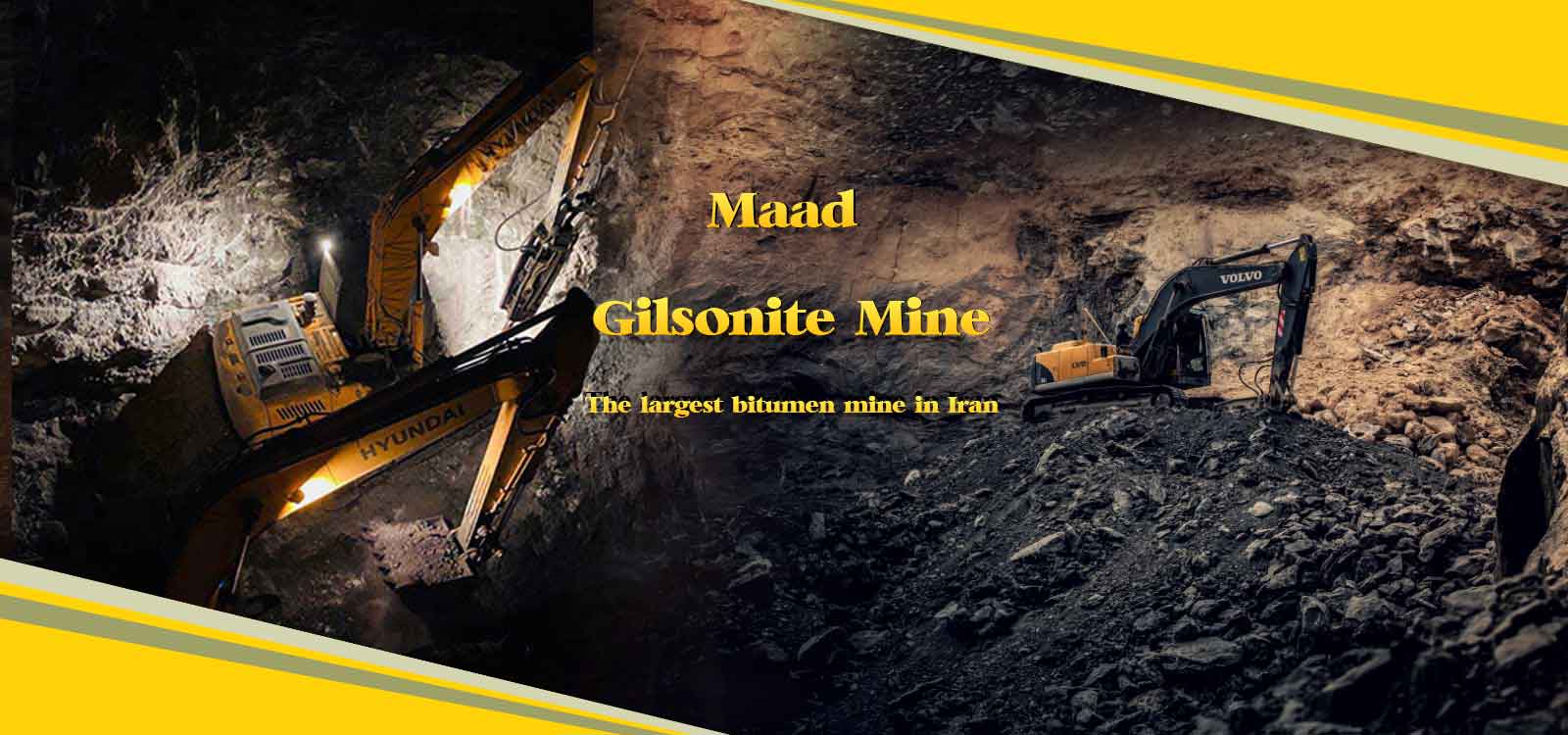

Maad Mining Company is the largest Gilsonite mine in western Iran

Bitumen (Gilsonite)

Products of Maad Company

Exploration and mining

Micronized bitumen powder

Direct from the Maad mine

Mining of Gilsonite

Appreciation meeting of sample industrial and mining units of Kermanshah province

In line with the industrial and mineral development of the country, appreciation meetings of exemplary industrial and mineral units are one of the ways that the industrial and mineral trustees form to achieve these goals. In this regard, a meeting of appreciation and honoring of exemplary industrial and mining units of Kermanshah province was held with the presence of government and industrial officials.

Officials present at the meeting

This meeting was held with the presence of officials such as Kermanshah governor, MPs, head of Iran Mining House and head of Samat organization and general managers of organizations of Kermanshah province.

Existence of mineral units such as Gilsonite and Maad natural bitumen (Gol Marjan)

In this meeting, the successful and exemplary industrial and mining units of Kermanshah province were introduced. Meanwhile, Gilsonite mining unit and Maad natural bitumen (Gol Marjan) were introduced as successful industrial and mining units in Kermanshah province. This unit operates in the industrial and mining area of Kermanshah province with important mineral reserves, including gilsonite, and natural bitumen powder.

Honors in the field of productivity and extraction: Maad Mining Industrial Unit has improved its performance and productivity in its mining and exploration and extraction processes by taking advantage of its ever-increasing experience and technical knowledge. These honors have made Maad Mining Unit one of the top and most prestigious mining industrial units in the country.

Honors in the field of human resource management: Maad Mining Industrial Unit has won great honors by implementing appropriate strategies in the field of human resource management, improving the quality of its products and developing technology.

Honors in the field of pioneering: Maad Mining Industrial Unit is recognized as one of the pioneers of the natural bitumen mining industry in the country with its continuous efforts in the field of technological development and advancement of the Gilsonite mining industry, and the natural bitumen powder factory.

Honors in the development of Gilsonite products and natural bitumen powder: Maad Mineral Industrial Unit has achieved great success in the domestic and foreign markets by focusing on improving the quality of its products.

Honors of Maad Gilsonite mine in the field of safety: Considering the importance of safety in mining processes, Mad Mining Industrial Unit has focused on creating a safe and healthy environment for its employees, which is one of the great honors of Mad Mining Unit.

Introduction of the managing director and operator of the example of Maad mining unit (Gol Marjan)

Dr. Hossein Fouladpour attended the appreciation meeting of industrial and mining sample units as the representative of Maad mining unit (Gol Marjan). Maad mining unit (Gol Marjan) is one of the successful and exemplary mines of Kermanshah province with precious mineral reserves including gilsonite, natural bitumen (gilsonite powder). By using modern technologies and benefiting from the technical and scientific knowledge of specialists in this field, this unit has increased the productivity of the country's mineral reserves and is known as one of the exemplary mines of the country.

Introduction of Dr. Hossein Fouladpour as the best operator and owner of the mine

Dr. Hossein Foladpour works in the field of industry and mining as the manager and managing director of Maad Mining Unit (Gol Marjan). As one of the prominent and experienced experts in the field of mining and exploitation of mineral reserves, he helps to use more of the mineral capacities of the country.

Dr. Fouladpour, having many studies and experiences in the field of mining and mineral processing, works as the manager of Maad Mining Unit in the optimal use of mineral reserves and environmental protection. By using advanced methods of mineral extraction and processing, he tries to increase the productivity of mineral reserves and reduce the wastage of Gilsonite minerals in the process of exploitation of mineral reserves.

Due to Dr. Foladpour's experience and technical knowledge in the field of Gilsonite mining, he, as one of the specialists of Maad mining unit, optimizes the process of exploitation and processing of minerals and participates by creating favorable and optimal conditions in the exploitation process. It also helps in economic development and job creation in this area.

Activities of Gol Marjan Mining Unit

Gol Marjan Mining Unit is active in the field of gilsonite, natural bitumen extraction and uses advanced technologies to increase the productivity of high gilsonite mineral deposits and reduce the wastage of minerals. This unit is known as one of the successful industrial and mining units in Kermanshah province by carrying out activities related to the extraction, transportation and processing of natural bitumen (Gilsonite) and having its own natural bitumen powder factory.

Issues raised in the meeting

In this meeting, various issues were discussed in the industrial and mining fields. Improving the performance and productivity of industrial and mining units, creating new opportunities in the field of industry and mining, developing new technologies in this field, improving the conditions of employees and personnel, improving the level of investment, creating interaction between industrial and mining units. with universities and research centers, etc., were among the issues that were discussed in this meeting.

Importance of sample industrial and mining units

Model industrial and mining units such as Maad natural bitumen mine (Gilsonite) are known as examples for other similar units in the country due to their very good and successful performance in the industrial and mining fields and can serve as a model for the creation and development of similar units. be used in other regions of the country. Also, the experiences and technical and scientific knowledge gained by these units can help to increase the productivity of units of the same category and benefit from mineral reserves.

Conclusion

Holding appreciation meetings of exemplary industrial and mining units can be one of the effective tools in encouraging the participation of the private sector in industrial and mining development. Model industrial and mining units with very good and successful performance in industrial and mining fields are known as examples for other similar units in the country and can be used as a model for the creation and development of similar units in other regions of the country. . Gilsonite mineral units and Maad natural bitumen (Coral Flower) are known as successful industrial and mineral units in Kermanshah province.

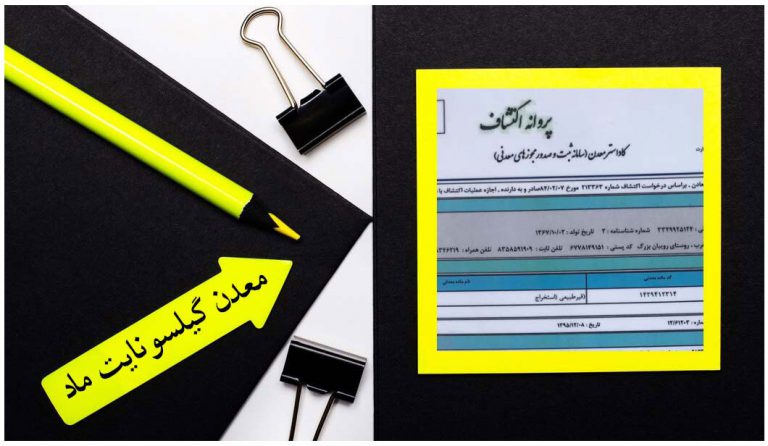

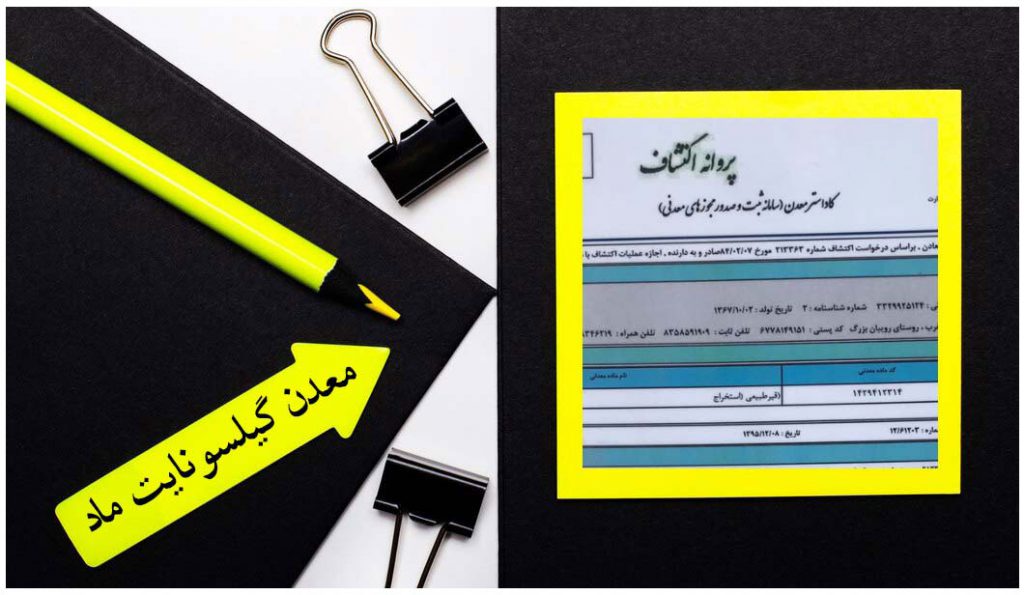

Maad company, in 2015, based on the exploration permit issued by the Ministry of Mines and Minerals, Kermanshah Province Industry, Mining and Trade Organization, started exploration operations for natural bitumen in a part of Maad mine area.

In the early stages of this project, with the help of expert researchers, in the field of geophysics, two-dimensional sampling or in other words, two-dimensional electrical imaging was done.

In this research, when geoelectric operations were carried out in a part of the range, it was found that Gilsonite mineral (natural bitumen) has been replaced from several centimeters to several meters, with alternating thicknesses, in the defined layers of the range.

During the contract concluded with the relevant company in this field, 7 profiles and 750 points were taken in the area by geoelectric method.

also :

- Construction of a trench with dimensions of 20 x 4 x 3 and with a volume of 120 cubic meters in the southeast entrance of Sinhkar.

- Carrying out physical and chemical analyses: Two samples of the existing mineral material have been sent to the relevant laboratory for analysis.

- Preparation of topographic map as well as preparation of geological map

- Preparing the report of discovery operations during mining In the map below, the location of Maad mine (Gol Marjan) is marked on the map.

1- Geophysical investigations indicate the presence of minerals with high specific electrical resistance (anhydrite and bitumen), natural bitumen (as well as minerals with low electrical resistance) green marls.

2- Natural bitumen anomalies and evaporative layers of anhydrite type gypsum with high specific strength related to Gachsaran formations were observed in all the collected profiles. that the arrangement and folding of the layers is in the northwest-southeast direction.

3- In profiles one to four, anomalies with medium to high resistances were introduced under the title of anomaly, natural bitumen (gilsonite) involved in dry anhydrite rock.

4- Several important faults and folds were revealed at the place of taking geophysical profiles. These areas are among the places prone to placing natural bitumen reservoirs.

5- Due to the high quality of natural bitumen available in the area, its specific weight is approximately 1.2.

6- Due to the fact that anomalies, signs of natural bitumen (Gilsonite), are observed at a depth of at least 35 meters, it can be acknowledged that the area in question has the economic potential of natural bitumen, which in order to access this Exploratory drilling of reserves should be continued up to the depth of 80 meters.

Also, after evaluating the natural bitumen reserve, for more accuracy and precision, accurate speculation operation was done by wagon drill and powder drilling.

Maad Mine Tailing Removal of overburden in Maad natural bitumen mine is an important mining operation that plays an important role in the extraction of bitumen, a valuable natural resource. This mine, which is located in Shek Maidan area, 25 km from Gilangreb city, has a rich history and has played a significant role in meeting the growing demand for bitumen products. Overburden removal, the process of cleaning the upper layers of soil and rock to access bitumen deposits, is one of the basic aspects of mining operations in Maad mine. This paper discusses the various techniques, equipment, environmental considerations, challenges, safety practices and future prospects associated with tailings removal at the Maad natural bitumen mine. By exploring these aspects, we can gain a comprehensive understanding of the complexities and developments in this critical step of the mining process.

Welcome to Maad natural bitumen mine, located in Kermanshah province, 25 km from GilanGharb city. This mine is a treasure trove of natural bitumen, a valuable and versatile resource that is used in various industries. The Maad mine is located in the Shek Maidan area at the best point in terms of natural bitumen gilsonite.

Another technique used in Maad mine waste removal is blasting. In this method, controlled explosions are carried out to break the covering rock and facilitate its extraction. Trained technicians strategically place explosives in predetermined locations, ensuring minimal damage to the surrounding environment. When blasting occurs, the loosened material is later excavated using machinery.

Logging and overburden drilling require powerful machinery that can efficiently move large volumes of material. In Maad natural bitumen mine, heavy machinery such as bulldozers, excavators and transport trucks are usually used. These machines are equipped with powerful engines and robust attachments to handle challenging terrain and remove excess load efficiently.

According to the determination of Gilsonite mineral reserve (natural bitumen) of Maad Mine, the applicable technical solutions were identified and analyzed for the tailing removal of Maad Mine. Also, by using the expertise of experienced engineers, Maad Mine, the best method of overburden removal, before Extraction was determined. With the round-the-clock efforts of Mad Company's hardworking personnel, and high safety, the mine overburden removal operation was completed.

Gilsonite, a unique and valuable natural resource, is widely recognized for its applications in various industries such as energy, construction and infrastructure. Maad mine, located in Gilangreb city in Kermanshah province, is a prominent source of gilsonite extraction. The purpose of this article is to provide an overview of Gilsonite mining operations in Maad mine, to examine geological features, mining methods, challenges and opportunities. By elucidating the important role of the Maad mine in Gilsonite extraction, this paper seeks to increase the understanding of this valuable natural resource.

The Maad mine is located in an area known for its abundant gilsonite deposits. This mine, which is located in the northwest of Iran in Kermanshah province and in Gilangreb city, has been a prominent source of Gilsonite extraction for several decades. The favorable geological conditions in this area make it an ideal place for mining operations.

Gilsonite deposits at the Maad mine exhibit distinctive characteristics that contribute to their exceptional quality. Mineral resin is usually found in veins or cavities in sedimentary rocks. These deposits contain a high concentration of hydrocarbons, which gives Gilsonite its unique properties.

Gilsonite formation is the result of complex geological processes that have occurred over millions of years. The organic-rich sediments, combined with heat and pressure, are believed to have converted plant and animal matter into the hydrocarbon-rich mineral resin we know as gilsonite. These processes included the gradual decomposition and transformation of organic matter in an environment suitable for the formation of hydrocarbons.

In the early stages of Gilsonite extraction in Maad mine, traditional mining methods such as surface mining and underground mining were used. Surface mining involved the removal of overlying rock and soil to access deposits of gilsonite near the surface, while underground mining involved the construction of tunnels and shafts to access deeper deposits.

With the advancement of mining methods, modern technologies and equipment have been introduced in Maad mine to improve efficiency and minimize environmental impact. These include automated drilling machines, advanced blasting techniques and advanced mining equipment. In addition, sustainable mining practices, such as reclamation and restoration efforts, are implemented to ensure long-term sustainability.

The mining process begins with the exploration and identification of Gilsonite deposits. Maad mine experts use geological surveys, remote sensing techniques and advanced imaging technologies to locate potential deposits. This detailed process involves analyzing geological formations and evaluating the quality and quantity of gilsonite deposits.

After identifying a deposit, Maad mining experts use various mining techniques to extract gilsonite. These methods include open pit mining, underground mining and in situ mining. Each technique is carefully selected based on factors such as sediment depth, accessibility, and environmental considerations. Maad mine experts prioritize sustainable practices to minimize the impact on the surrounding ecosystem.

When it comes to Gilsonite mining, Maad Mining experts don't rely on old methods. They use the power of advanced technologies to ensure efficient mining. From advanced drilling techniques to innovative machinery, Maad mine experts stay ahead of the game. Also, to identify more and better Gilsonite veins, a polar-dipole array was used. It should be noted that during the harvesting, changes were made in the location of the harvesting due to the characteristics of the region and to better understand the vein of the deposit.

The selected array is of the polar-bipolar type with a potential distance of 10 and 5 meters and the maximum flow lines are of variable sizes, which sometimes according to the obtained results, the depth resolution of the collection has changed. And places where there was a possibility of bitumen were implemented. The purpose of conducting geophysical studies was to know the depth trend of the bitumen vein, the location of the faults, the continuity under the ground, the possible changes in mineralization and the probability of its occurrence in the existing faults, joints and cracks in the region.

Finally, with the depth modeling of the deposit in the areas where there is the highest thickness of mineralization, the highest amount of abnormality and the probability of discontinuity or continuity, it was done for drilling operations. Using advanced drilling methods, Maad Mining Company can accurately reach the deepest Gilsonite deposits. This allows for maximum extraction and minimizes waste. In addition, Maad mining experts use advanced machinery that can control the unique properties of gilsonite and ensure a smooth extraction process.

Maad mining experts understand that safety is paramount in Gilsonite mining. They use strict safety protocols to protect workers and the environment. Advanced technologies are used to monitor the mining process and ensure a safe working environment.

At the same time, Maad mining experts are masters at optimizing productivity. They have mining techniques to minimize downtime and maximize output. The experts of Maad mine have determined the standard of Gilsonite extraction by combining efficiency and safety.

Maad mining experts play a vital role in Gilsonite extraction. With their expertise and advanced technologies, they ensure efficient mining while prioritizing safety and minimizing environmental impact. Their commitment to sustainable practices and partnerships set the standard for the industry. As the demand for Gilsonite increases, Maad's mining experts are well prepared to meet the challenges and contribute to the future success of the industry.

Maad mining experts are renowned for their extensive knowledge and expertise in Gilsonite mining. With years of experience, they have mastered the art of identifying, extracting and processing Gilsonite efficiently and sustainably. Their deep understanding of geological formations and mining techniques enables them to optimize the mining process and ensure the production of high quality gilsonite.

Maad mining experts have established strong collaborations and partnerships with industry leaders in various sectors. Through these partnerships, they have access to advanced technologies and resources that enable them to improve the mining process and meet the evolving demands of their customers. These collaborations also foster knowledge sharing and innovation, ensuring that Maad's mining experts remain at the forefront of the gilsonite mining industry.

While gilsonite mining has its benefits, it is not without its challenges. One of the main obstacles is the complex geology of the deposit, which makes it difficult to effectively extract this mineral. Gilsonite's high viscosity also creates challenges during the extraction process, requiring specialized equipment and techniques. In addition, operational challenges such as manpower and logistical issues must be addressed to optimize mining efforts.

Despite the challenges, gilsonite mining offers exciting opportunities for industry innovation. As technology advances, new extraction methods and equipment can be developed to maximize efficiency and minimize environmental impact. Collaboration between researchers, engineers and mining companies can lead to improvements in the extraction process. Moreover, the growing demand for gilsonite in various industries opens doors for economic development and growth.

Due to the increasing demand for gilsonite and its various applications, the industry is expected to witness significant growth in the coming years. As infrastructure development and energy needs continue to expand globally, demand for Gilsonite will follow suit. This creates opportunities for mining companies like Maad to meet increasing demands while promoting sustainable practices. With the right investment, research and commitment to environmental stewardship, the future of gilsonite mining looks promising.

In conclusion, Gilsonite extraction is a complex process that requires knowledge and expertise. Maad mining experts have established themselves as industry leaders by using advanced techniques to extract and refine Gilsonite efficiently. Their commitment to sustainability and environmental safety furthers their vital role in the industry. As demand for Gilsonite continues to grow, collaboration between Maad Mining and other stakeholders will be essential to overcome future challenges and ensure a sustainable supply of this valuable resource. Through their expertise and commitment, Maad mining experts are paving the way for a thriving gilsonite industry.

As a result, the Maad mine plays a vital role in the extraction of gilsonite, a valuable resource with diverse applications. Through its geological features and advanced mining methods, Maad Mine helps meet the demand for gilsonite in various industries. With its rich reserves and ongoing efforts, Maad Mine remains a key player in the gilsonite industry, ensuring that this versatile source will be available for years to come. to be released in the future.

How is gilsonite extracted in Maad mine? Gilsonite mining in Maad mine involves a combination of traditional mining techniques and modern technologies. First, surface or underground deposits are located and accessible. Gilsonite-rich rock is then extracted using drilling, blasting and drilling methods. Advanced equipment is used to crush, grind, and separate the ore, followed by refining processes to purify the mined gilsonite for commercial use. How does Maad mining expertise help Gilsonite mining? The experts of Maad mine have extensive knowledge and experience in the field of Gilsonite extraction. They use advanced techniques and advanced technologies to effectively identify, mine and process Gilsonite deposits. Their expertise ensures safety, productivity and optimal use of resources during the mining process. What are the future prospects and challenges in Gilsonite mining? The future prospect of gilsonite extraction is promising due to the increasing demand for its applications in various industries. However, challenges such as regulatory compliance, fluctuating market conditions, and the need for continuous innovation in mining techniques may pose obstacles. Through collaboration and expertise, Maad Mining experts aim to overcome these challenges and ensure a sustainable supply of gilsonite for the future.Mineral Mining and Trading Group

Having one of the highest quality Gilsonite (natural bitumen) mines in Iran and successful experiences in the field of sales and export of natural bitumen has the ability to deliver natural bitumen products and micronized Gilsonite (natural bitumen) powder in all different grades in the highest tonnage required.

You can see the latest articles and news

of Maad Company here

The method of producing complete white bitumen with the details ...

Bitumen weight loss test: Bitumen weight loss test is a ...

white bitumen , a versatile material with a wide range ...

Gilsonite min exploration methods : Gilsonite, also known as uintaite, ...